Align

A Build for Anyone

Disability-friendly design doesn’t need to feel medical-related. This project reimagines a “fun” product niche for those with hand mobility limitations.

Unlike the tiny pieces most buildable kits are known for, the Align Lantern Kit features larger, standardized parts for easier gripping, along with a stabilizing LED core that reduces physical strain.

Duration

4 weeks, July 2025

- - - - - - - - - - - - - - - - - - - - - - - -

Type

Industrial Design

- - - - - - - - - - - - - - - - - - - - - - - -

Tools

Procreate, Solidworks, KeyShot

Mission

Striving for Universality

In the current era of design, inclusion and accessibility are essential elements. I question whether the problems of underserved demographics are truly niche or rather exaggerated by an institutional standard that resists accommodation.

In the following project, the aim was to create a universal product that bridges the experience of a typical user with that of a disabled user.

Research

Defining the User

Informed by posts from online forums, I reviewed countless firsthand accounts of products lacking accessibility, products that support disabled users, and most importantly, the ways disabled users retain joy throughout their daily lives.

It is naive to think one solution can solve the needs of every type of disability. Therefore, it was necessary to narrow down my demographic to confront specified issues.

Age: Young adult (18-30yrs)

Disability:

-

Physical

-

Low mobility and strength in limbs

-

Assumption that they can use their upper body (hands, neck, etc.)

-

The general issue is sustaining activities due to associated pain

Niche: Hobbies that encourage creative thinking and play, even in a weak state

Product: Buildable kits

"I miss doing the things that make me feel like 'myself.' " -Reddit User

Competitive Landscape & Moodboarding Analogous Products

As an avid Lego enthusiast, I trusted my initial knowledge of the buildable kit category to guide competitor research and moodboarding.

Beyond typical puzzle-like products, I sought to understand disability friendly items and other analogous forms.

Buildable Kits:

The Consumer Journey

By tracking the journey of a typical user, it was easy to pinpoint interactions that need accessibility improvements. Due to the weak endurance of my target demographic, my interest lay in the relationship between the Build and Pause Stages mapped below.

_edited.jpg)

Brainstorming + Ideation

Breaking Forms into Pieces

This project required exploring individual pieces and the many ways they can interact to create whole forms. My extensive brainstorming revealed a profound difference between using a slot fit versus a sharp click of two parts.

The geometric nature of building blocks influenced what imagery could be represented in a final form. Ultimately, I found potential in creating a lantern design. This structure could encompass adult complexity without the strain of small piece sizes.

Velcro

Grips

Screw

Slots

Clicks

Clicks

Fluid shapes

Slide

Insert

Bridge

Magnet

Hook

3rd hand tool platform

How can I join two pieces together without extreme force?

How can I transform the kit's packaging for a 2nd purpose?

Device that ensures stability

Exploring the aesthetic and functional versatilty of a lantern kit's pieces.

Round Form

Square Form

Diamond Form

How you stack determines the design

Core serves as the light and stable base

Size range: Small, Medium, Large

Designing individual pieces and defining how they interact to build a final lantern.

How was Accessibility Addressed in the Build?

-

Unlike traditional buidable kits, individual pieces were sized up for easier gripping. This element is integral for those with poor fine motor skills.

-

Holes and spaces meant for inserting or sliding together pieces are also larger than normal. Universally sized 25mm x 5mm x 5 mm across all parts, allowing for less precision needed when building.

-

The LED core that illuminates the lantern serves as a foundation to stabilize the building experience. It is similar to a third-hand tool that relieves physical pressure.

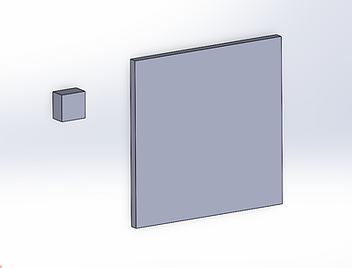

A 2x2 Lego brick measures 16mm x 16mm x 9.6mm.

An Align lantern base piece measures 100mm x 100mm x 5mm.

Refinement

Prototyping through CAD

The sketches created during ideation guided my 3D modeling process. I worked in a backwards manner, first modeling each form before breaking it up into individual pieces. Then, I proved through digital assembly that the pieces fit correctly back together.

All piece designs are repeated throughout the build to optimize physical production. For example, the base piece of each form is identical.

Three unique builds that can be stacked to create any desired structure.

Reflections

Benefiting more people

than you might think

Similar to the accounts of disabled users, I came across stories of elderly users who wanted to build kits with their grandkids, but physical endurance prevented them from doing so. We should note that physical limits also affect young adults if they spend many hours working on a large kit. The key difference is just how quickly each user hits their limit.

As a designer, I strive to improve everyday experiences for people. I believe this is especially important in creative industries, where imagination and entertainment often provide the most consistent and meaningful sources of joy.

Product accessibility shouldn’t be a dramatic effort to stay socially responsible—it should be standard practice. Without even noticing, abled users typically benefit from accessible features. So, where is the harm in thinking universally?

© 2025 Mayah Hamaoui.